Three Key Decisions for an Optimal Ejection SystemFebruary 19, 2021Paul ThalGeneral ManagerThal PrecisionInjection molders want plastic parts to eject easily, consistently, quickly. Parts getting stuck causes damage and can break mold components, resulting in longer cycle times, manufacturing delays and increased costs. An experienced moldmaker knows how to manage the complexities of your mold design […]

Tag Archives: plastic mold design

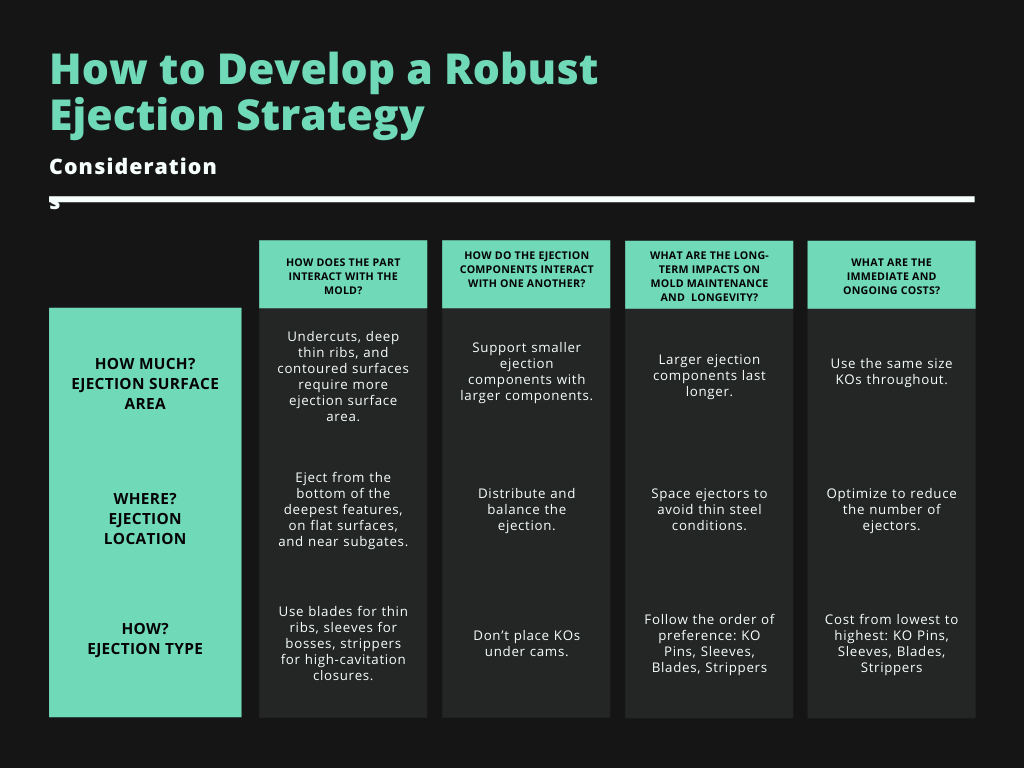

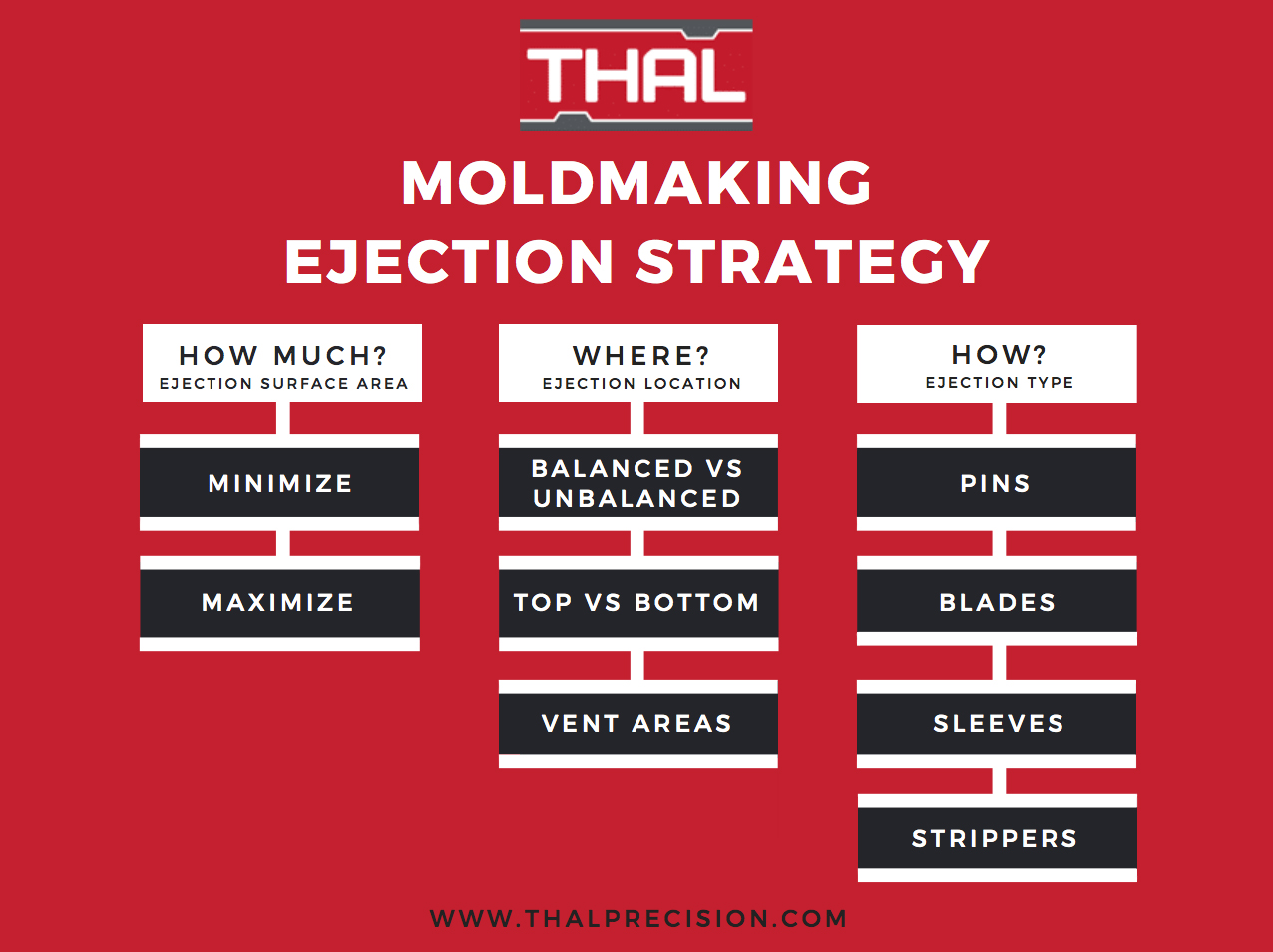

How to Develop a Robust Ejection Strategy For Your Plastic Injection Mold Design

As an injection molder you want your plastic parts to eject easily, consistently, and quickly. When parts get stuck in the mold, they get damaged, or the mold components break. In either case, you do not get the mold performance you deserve. These issues will cause longer cycle times with increased costs and manufacturing delays. After […]

The Moldmaker’s Guide to a Robust Ejection Strategy

What are the last words any plastic injection molding manager wants to hear? “Something happened. We have to stop the mold and pull it from the press.” A panicked onslaught of questions follow. “What happened? What do we need to do? How long will the moldmaker take? What does this do to our production schedule?”Any […]